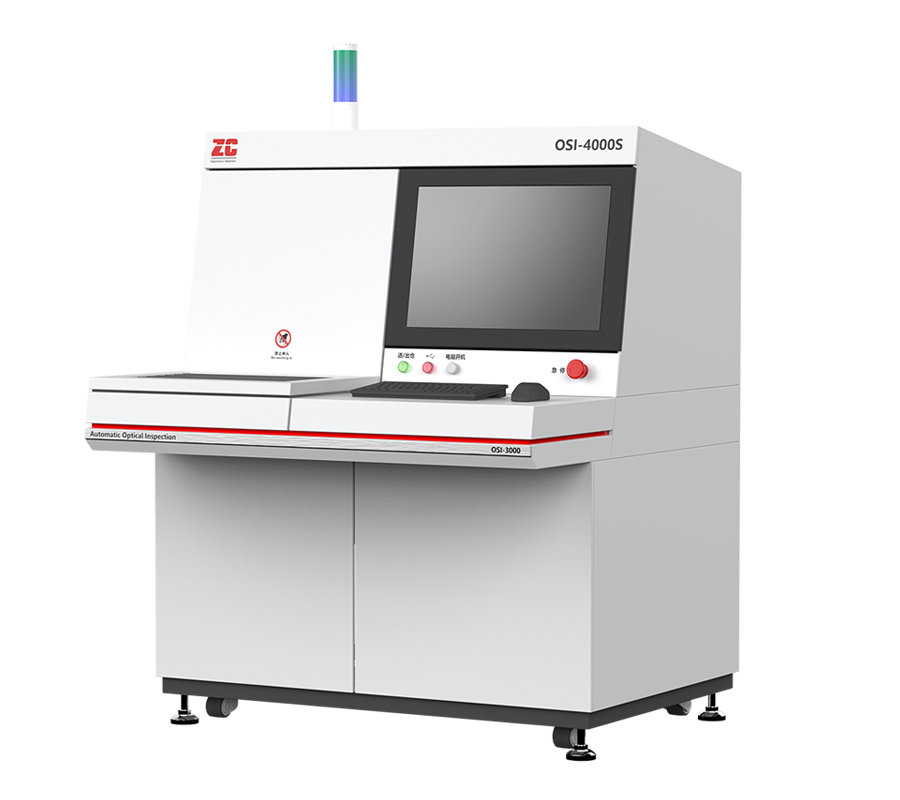

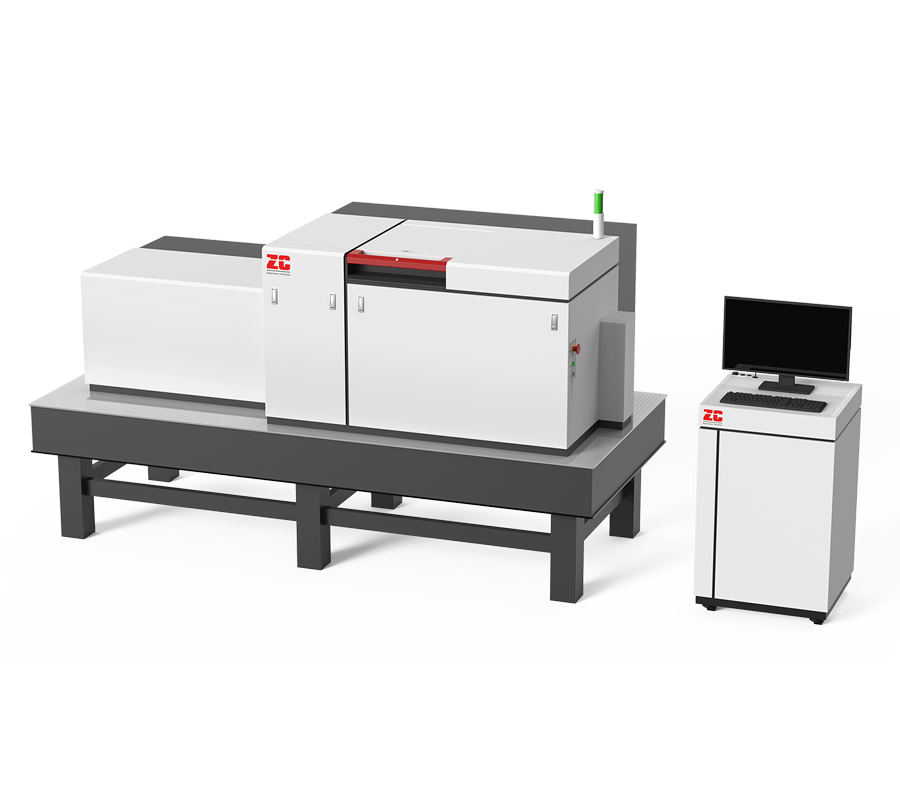

The Defect Inspection System For Planar Components (AOSI-4000F ) is designed for fully automated visual quality inspection of planar optical components. It features high automation, batch loading/unloading, intelligent detection, simulation testing, and generates inspection reports for each component. The equipment also produces inspection logs for analyzing quality trends, defect statistics, and process optimization over time.

|

Defect Inspection System For Planar Components |

|

|

Model |

AOSI-4000F |

|

Sample Type |

Flat,Spherical,Aspherical lenses |

|

Typical Sample Size*1 |

∅5mm ~ ∅30mm |

|

Missed Defect Rate |

≤1% |

|

False Alarm Rate |

≤10% |

|

Max Throughput |

2400pcs/h @ ∅10mm, 40/20 |

|

Loading/Unloading |

Fully automated, customizable user interface |

|

Compliance Standards*2 |

MIL-PRF-13830B |

|

Rated Power |

8KW |

|

Power Supply |

220V, 50Hz |

|

Compressed Air |

0.6MPa~0.8MPa, 300L/Min |

|

Dimensions*3 |

1865mm ×1565mm × 2165mm |

|

Weight |

1000Kg |

*1:Sample size can be customized.

*2:Detection standards are adjustable per requirements.

*3:Dimensions are adaptable to installation conditions.

Note: We can provide customized instruments of the same type and related testing solutions according to customer requirements.

-

High-Sensitivity Optical Detection System1

-

Flexible Detection Modules2

-

Standard Compliance3

-

High Automation4

-

Adaptive Collector5

-

Inspection Log Analytics6

-

High-Protection Environment7

-

One-Click Operation8

-

AI Algorithms9

英文

英文 中文

中文